Life span

Safe, clean, light.

Plastic pallets are allround talents and the clear winner in a direct comparison with wooden pallets: they have a significantly longer service life, need to be replaced less often and are therefore a sustainable investment. Neither pesticides nor mould can grow in plastic pallets - this has two advantages: On the one hand, our products are therefore also suitable for the food and pharmaceutical sectors, and on the other hand, they do not have to be fumigated and documented at high cost when exported. In addition, pallets made of recycled plastic are particularly environmentally friendly.

Plastic pallets have an unmistakably longer service life than wooden pallets. Due to a significantly higher number of rotations, plastic pallets have to be replaced much less often.

Hygiene

A plastic pallet is free of mould and fungal attacks. It is easier to clean and for the most part, with closed constructions, bacterias do not stand a chance. For these reasons, a plastic pallet is an excellent fit for any industry where hygiene is an important factor (e.g. food, pharmary, and much more).

Export

Since no pesticides can settle in plastic pallets, they do not have to be fumigated and provided with the necessary papers at high cost when exported.

Minimal damage

With plastic pallets there are no protruding nails or splinters that could damage the goods or even injure an employee.

Low dead weight

In most cases, plastic pallets are lighter than comparable wooden pallets. They are weight neutral and do not absorb water.

Sustainability

Almost all production waste is recycled and reintroduced into the process. Pallets made of recycled plastic are therefore particularly environmentally friendly.

Flexibility

You have the freedom to choose from our various standard dimensions, or to have pallets made for your requirements.

KIGA standard dimensions:

400 x 600 mm, 600 x 800 mm,

800 x 1.200 mm, 1.000 x 1.200 mm,

1.140 x 1.140 mm, 1.200 x 1.200 mm und XXL.

Sondergrößen XS - XXL

Sie benötigen eine Sondergröße für Kunststoffverpackungen, weil Ihre Produkte größer sind als der Standard? Kein Problem! Sondergrößen für Kunststoffverpackungen sind bei uns Standard!

Sizes and standards

Quarter pallet – 400 x 600 mm

The quarter-sized display pallet is ideal for presenting your products in the showroom and/or for the transport of smaller packing pieces. The quarter pallet gets its name from the relation to the size of a standard europallet.

Half pallet – 600 x 800 mm

Thanks to its size and flexibility, this display pallet is excellent for the transport and storage of boxes in retail.

Europallet – 800 x 1.200 mm (CP 2)

This is the plastic version of the europallet, which was developed by the International Union of Railways (UIC) in 1961. KIGA plastic pallets in europallet dimensions are available in different versions – depending on the usage.

Industrial pallet – 1.000 x 1.200 mm (CP 1)

This industrial pallet, which is mostly being fitted with 5 skids in Great Britain, is another European industry standard next to the europallet. The industrial pallet is slightly larger than the europallet.

Container pallet – 1.140 x 1.140 mm (CP 3)

Dieses Maß ist speziell für den Container-versand in Überseecontainern entwickelt,

da diese ein amerikanisches Maß (Fuß) verwenden und daher nicht mit den Europaletten kompatibel sind. Das qua-dratische Maß verspricht hier größtmögliche Raumausnutzung und Ladungssicherung.

Barrel pallets – 1.200 x 1.200 mm

The barrel pallet is square and has room for 4 barrels. It is also coordinated with the europallet standard, with six arranged quarter pallets combining to the basic measurements of 1.200 x 1.200 mm.

Entry dimensions of a pallet

a Width/narrow side

b Length/long side

c Height

d Forklift ground clearance

e Maximum entry height

f Base width

g Maximum entry width

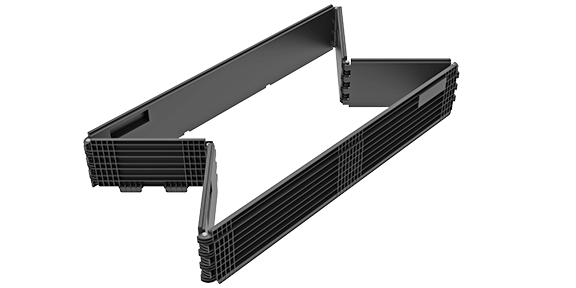

Structural shapes of KIGA pallets

No matter if die cast, pressed, or deep-drawn – KIGA offers various plastic pallet in various structural shapes. Here are some examples:

with open deck

with closed deck

nestable plastic pallets with feet

Mono block pallets with skids

with corrugated bottom deck

with closed bottom deck

open/closed skids

Top deck

The top deck of KIGA plastic pallets can be roughly split in two categories: open and closed. An open top deck saves material and therefore weight, though in some parts at the cost of stability and security. A closed upper deck prevents loose material from trickling through as well as preventing pressure marks on the transported or stored product. It is also very easy to clean and therefore hygienic. Open decks on the other hand let the air circulate and as such might even act refrigerative. Whether an open or closed top deck should be used, should therefore be decided in regards to the usage.

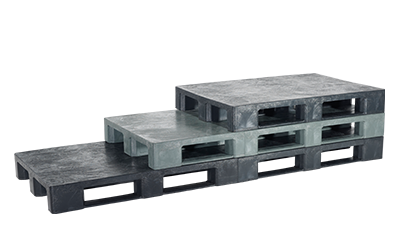

Base

In most cases, the underside of a pallet is an even more crucial factor than the top deck. Depending on the usage, more or less stability is needed to carry the active forces and weights – stability that is mainly determined by the base of the plastic pallet. Different foot or skid systems have different advantaes or disadvantages while in use. The distinctions here are for example nestable, stackable or for usage in high rack systems.

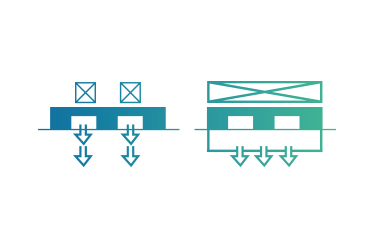

Feet

Plastic pallets with 4, 6 or 9 feet – depending on pallet size and usage – make multiple pallets nestable. This decreases the room the empty pallets take up when being stored or transported by up to 75%. The feet make it possible to drive under the pallets from every side, but: a pallet fitted with feet can not carry as much weight as a pallet with skids. Pallets with feet are also not suitable for roller conveyors or high racks.

Skids

KIGA offers you pallets with 3 or 5 skids. The skids stabilise the pallets and make them resilient when being used with medium to heavyweight goods in automated transport- and high rack systems. Skids that are reinforced with metal can take especially heavy goods.

Slipguard

The slipguard rims that are mounted on the edges of the top deck stabilise and fixate the loaded goods and keep it from slipping. Empty pallets are also fixated this way when they are being stacked.

Rounded edges

Rounded edges on top deck, skids and feet protect the pallet from damage from fastening material, e.g. tightening straps or foil. They also guarantee safe handling with lift trucks and forklifts and reduce the danger of injury through splinters and edges.

Iron reinforcement

Many pallets are available with iron reinforcements. The iron reinforcement is – depending on type of pallet – installed in the top deck and/or the skids. Iron reinforcements will increase stability in warmer temperatures, for example in high rack storages or on roller conveyors.

Load capacities of plastic pallets

The highest permitted gross weight of the load that is to be transported is called the load capacity of a pallet and is as such an important factor when choosing respectively producing a pallet. A standard wooden europallet in unused condition generally has a maximum load capacity of 1,5 tonnes. Since the load capacity does not say anything about the quality of the pallet, some other factors have to be taken into account depending on usage and requirements – for example the loads. In practice, there are three types of loads:

Static load

The load or respectively the weight of the goods that are to be transported when loaded on a pallet that is standing on an even and fixed surface, is called the static load.

Dynamic load

The dynamic load is generally the most important type of load for a good, since pallets are most commonly used for transporting. It describes the permitted gross weight of goods that are loaded on a pallet while being transported with a forklift.

Bearing load in high rise racks

The permitted gross weight of goods on a pallet, while the pallet rests on the steel beams of a high rack system with only the edges of its feet or skids, is called the bearing load in high rise racks. The bearing load is specified taking into account the material- and temperature-dependent bending of the plastic pallet through stress.

Nominal load, working load, point load and surface load

For the various kinds of loads (static, dynamic and high rise rack), one can determine a nominal load and a working load. The nominal load in this case is a theoretical, the working load a practical type of load. These types of loads are defined by the norm ISO 8611.

The point load and the surface load respectively identify the weight of a loaded good or a loaded pallet on corresponding single points or the whole surface.

Material

Generally, there are three different types of material you can choose from with KIGA.

Plastic products made from virgin material are food safe, which means foodstuffs and pharmaceutical products are allowed to come into contact with it, even without packaging.

Our ecologically friendly and sustainable ECO pallets are made from 100% recycled plastic material. With products from recycled plastic material, foodstuffs or pharmaceutical products have to have a packagin. They are not allowed to come into direct contact with the pallet. Still, these plastic products – especially in combination with with easily cleanable surfaces – are generally food compatible.

Plastic pallets made from ESD-safe (electrostatic discharge) material are ideal for the transport of conductive or easily flammable products, since they prevent electrostatic discharge damaging your products or even hurting your employees.

Temperature resistance capabilites of plastic depend on the material used. For the mostly used PE-material, temperature resistance ranges from -30 °C to +70 °C.

Special features on demand

Barcode and RFID-transponders

The RFID-transponders, which are enclosed in the plastic during the production of your pallet, make it possible to track your pallet and the route it takes. As opposed to barcodes, which are attached to the outer part of your pallet, the RFID-transponders are protected from damage and dirt.

Individual surfaces

Without having to use a new basic tool, KIGA offers you the possibility to change the top deck of various types of pallets according to your usage of the pallet. Almost any type of surface is possible and will be developed, designed, and produced in coordination with you.

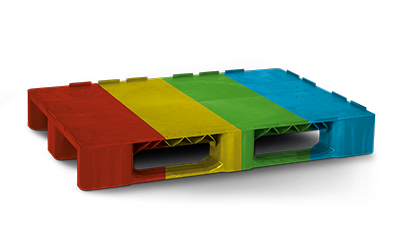

Colour

Many KIGA plastic pallets are available in various colours made from virgin material plastics.

ESD (electrostatic discharge)

Conductive and/or easily flammable products need a high level of security. A single spark in an electrically isolating material can cause a short but very strong current pulse and can therefore be very dangerous for humans and transported goods alike. The KIGA ESD product line has surface resistances according to your specifications, which prevent electronic discharge damaging your product or even injuring your employees. KIGA ESD products protect you from static fields and prevent extremely fast discharges – all the while living up to our high security standards. Even small numbers of pieces are possible thanks to our on demand service including thermoforming production.

Special sizes

With its XS – XXL-series, KIGA set itself apart from its competitors and developed a one-of-a-kind product solution fitted to your specifications. Even though it is a special production, you will not have to pay for tool costs, since we work with a specialized mirror welding process which allows us the lengthening and broadening of our standard products to any size we desire. Sizes up to 4.000 x 2.800 mm and more are no problem at all. The XS – XXL series are of course available with all variations and special features from the standard series.